Stress Analysis Skills

- FEA

- Programming

Bar End Weight Fix

This part was designed to be 3D printed and press fit into a handlebar to serve as a mounting point for a bar end weight and hand guards on a motor cycle.

Calculations in Python were used to confirm that a 3D printed ABS part would be a reasonable solution based on stress due to press fit, pull out force of press fit and strength of threads.

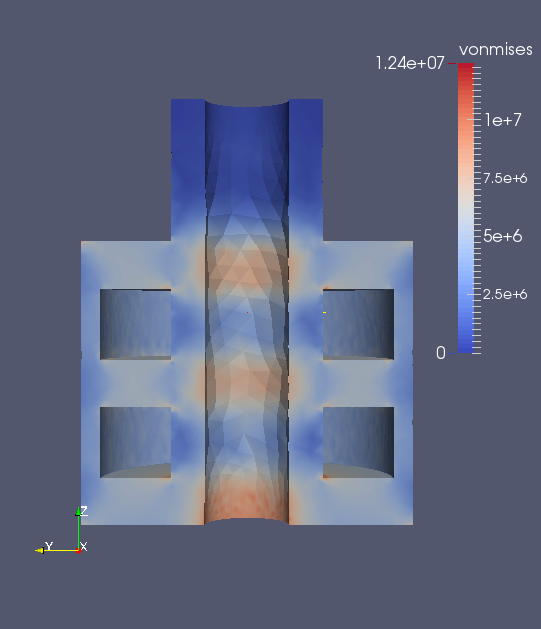

A simplified 3D model of the part was created and imported into ELMER for meshing and FEA. The FEA was run as a static linear analysis using standard ABS material properties as no data was available on how 3D printing would affect part strength. The part was loaded by defining the displacement of the outside surface as the max interference of the press fit. The results showed that the highest stress in the part was below yield strength, confirming that a linear analysis was the correct choice. The part geometry was iteratively optimized to remove excess material using additional FEA runs as guidance.

Analysis results shown in Paraview: